Product Description:

Cementing Float Equipment

Product Overview

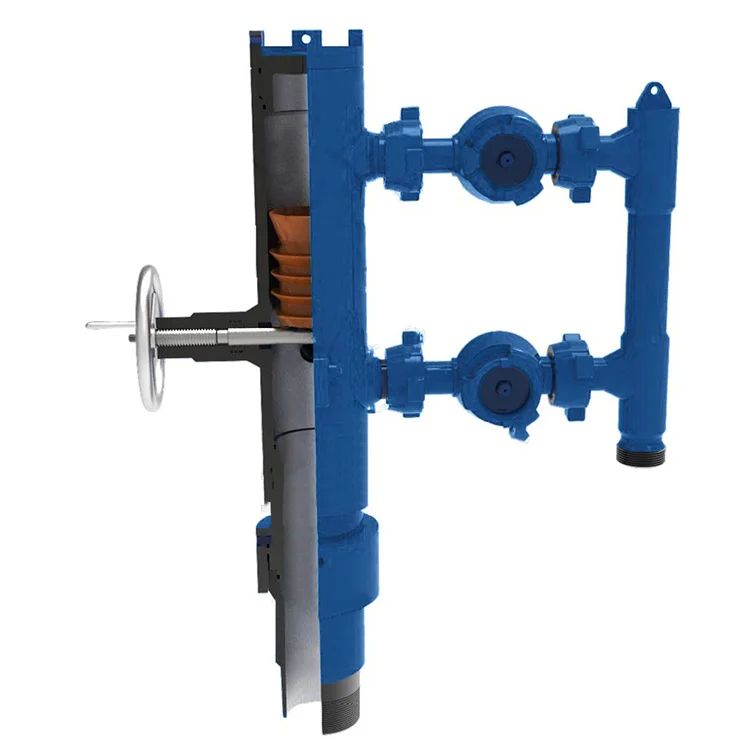

The Cementing Float Equipment is a key component in the cementing process of oil and gas wells. It is designed to provide a reliable seal and prevent backflow of cement during the cementing operation. This product is highly customizable to meet the specific needs of different well conditions.

Size: Customized

The Cementing Float Equipment is available in various sizes to accommodate different casing sizes and wellbore conditions. Our team of experts will work closely with you to determine the best size for your specific well, ensuring a perfect fit and optimal performance.

Durability: High

Our Cementing Float Equipment is made of high-quality steel, ensuring durability and long-term performance in even the harshest well environments. It is designed to withstand high pressure and extreme temperatures, making it a reliable choice for your cementing operation.

Material: Steel

The use of steel as the main material for our Cementing Float Equipment provides several advantages. Steel is known for its strength and resilience, making it a suitable choice for oil and gas well equipment. It is also resistant to corrosion, ensuring the longevity of the product even in corrosive well conditions.

Performance: Excellent

Our Cementing Float Equipment is designed and manufactured to provide excellent performance in the cementing process. It creates a reliable seal and allows for efficient cement placement, ensuring the success of your cementing operation. Its high-quality construction and customizable design contribute to its outstanding performance.

Resistance: High

The Cementing Float Equipment is built to withstand high pressure and extreme temperatures, making it highly resistant to the harsh conditions of oil and gas wells. It is also resistant to corrosion, ensuring its longevity even in corrosive environments. This high level of resistance makes it a reliable and durable choice for your cementing operation.

Overall, the Cementing Float Equipment is a crucial component in the cementing process, providing a reliable seal and preventing backflow of cement. Its customizable size, high durability, steel material, excellent performance, and high resistance make it an essential tool in the oil and gas industry. Trust our Cementing Float Gear to enhance the efficiency and success of your cementing operation.

Contact us today to learn more about our Cementing Float Instrumentation and how it can benefit your well cementing process.

Features:

- Product Name: Cementing Float Equipment

- Temperature: High

- Pressure: High

- Corrosion: Low

- Size: Customized

- Connection: Threaded

- Key Features:

- Cementing Float Machinery

- Cementing Float Apparatus

- Cementing Float Tool

Technical Parameters:

| Cementing Float Instrument |

|

| Cementing Float Device |

|

| Cementing Float Gear |

|

| Durability |

High |

| Corrosion |

Low |

| Cost |

Reasonable |

| Weight |

Light |

| Performance |

Excellent |

| Pressure |

High |

| Connection |

Threaded |

| Application |

Cementing |

| Resistance |

High |

| Material |

Steel |

Applications:

Product Description

The Cementing Float Equipment, also known as cementing float apparatus, cementing float device, cementing float gear or cementing float tool, is a crucial component in the cementing process for oil and gas wells. It is designed to assist in the placement of cement at the desired depth during the well construction process.

Brand Name: sws

SWS Cementing Float Equipment is a trusted and reliable brand in the oil and gas industry. Our products are known for their high quality and excellent performance, making them the preferred choice of many oil and gas companies.

Model Number: 5

The Cementing Float Equipment from SWS comes in various models to suit different wellbore sizes and specifications. Model number 5 is one of our popular models, suitable for most standard cementing operations.

Place of Origin: China

SWS Cementing Float Equipment is proudly made in China. Our state-of-the-art manufacturing facilities and skilled workers ensure that our products meet the highest standards of quality and reliability.

Cost: Reasonable

At SWS, we understand the importance of cost-effectiveness in the oil and gas industry. That's why we offer our Cementing Float Equipment at a reasonable price without compromising on quality. Our products provide excellent value for money and help our customers save on their overall project cost.

Weight: Light

The Cementing Float Equipment from SWS is designed with lightweight materials, making it easy to handle and transport. This not only reduces the risk of injuries during installation but also helps to save time and labor costs.

Application: Cementing

As the name suggests, the primary application of SWS Cementing Float Equipment is in cementing operations for oil and gas wells. It is used to prevent the backflow of cement during the placement process, ensuring a secure and reliable cement barrier in the wellbore.

Corrosion: Low

SWS Cementing Float Equipment is designed to have low corrosion levels, making it suitable for use in harsh and corrosive environments. This helps to prolong the lifespan of the equipment, ensuring that it can withstand the rigors of oil and gas operations.

Resistance: High

Our Cementing Float Equipment is built to withstand high pressures and temperatures, making it an ideal tool for use in challenging well conditions. It is also resistant to abrasion and wear, ensuring long-term performance and reliability.

Product Usage Scenario

SWS Cementing Float Equipment is commonly used in the following scenarios:

- During primary cementing operations to prevent backflow of cement

- In deviated or horizontal wellbores where maintaining a consistent cement column can be challenging

- In wells with lost circulation zones to prevent cement from being lost into the formation

- In wells where there is a risk of gas migration, the Cementing Float Equipment acts as a barrier to prevent gas from entering the cement slurry

Overall, the Cementing Float Equipment from SWS is an essential tool for ensuring a successful and efficient cementing process in oil and gas wells. Its reliable performance, low corrosion, and high resistance make it a valuable asset for any cementing operation.

Customization:

Customization Service for Cementing Float Equipment

Brand Name: sws

Model Number: 5

Place of Origin: China

Pressure: High

Material: Steel

Stability: High

Resistance: High

Size: Customized

At sws, we understand that every project is unique and requires specific solutions. That's why we offer a customized service for our Cementing Float Equipment, ensuring that it meets your exact needs and specifications.

Our Cementing Float Machinery is designed to provide high pressure capabilities, making it suitable for various applications. Made with top-quality steel material, it ensures durability and reliability in even the most challenging conditions.

With our customization service, you can choose the size that best fits your project requirements. We guarantee high stability and resistance for our Cementing Float Device, ensuring optimal performance and safety.

Trust sws to provide the perfect solution for your project with our customized Cementing Float Equipment. Contact us now to discuss your specific needs and let us help you achieve success.

Support and Services:

Cementing Float Equipment Technical Support and Services

At Cementing Float Equipment, we are committed to providing our customers with the highest quality products and services. Our team of experts is dedicated to delivering exceptional technical support and services to ensure the success of your cementing operations.

Technical Support

Our technical support team is available 24/7 to assist with any questions or concerns regarding our Cementing Float Equipment. Our knowledgeable and experienced technicians are trained to troubleshoot and resolve any issues that may arise during your cementing operations.

We also provide technical training to our customers, ensuring that they are equipped with the necessary knowledge and skills to handle our products safely and efficiently. Our training programs cover topics such as proper installation, maintenance, and troubleshooting techniques.

Services

In addition to technical support, we offer a range of services to help our customers achieve optimal results with our Cementing Float Equipment. These services include:

- Installation and commissioning assistance

- On-site support during cementing operations

- Equipment rental and leasing

- Equipment maintenance and repair

- Customized solutions for specific project needs

Our goal is to provide our customers with a hassle-free experience, allowing them to focus on their cementing operations while we handle the technical aspects.

Contact Us

For any technical support or service inquiries, please contact our customer service team at 555-555-5555 or email us at support@cementingfloatequipment.com. We are always happy to assist and ensure the success of your cementing operations.

Thank you for choosing Cementing Float Equipment. We look forward to providing you with exceptional technical support and services.

Packing and Shipping:

Packaging and Shipping for Cementing Float Equipment

Our Cementing Float Equipment is carefully packaged and shipped to ensure safe and secure delivery to our valued customers. The following steps outline the packaging and shipping process:

Packaging Process

- Each piece of Cementing Float Equipment is individually wrapped in protective materials to prevent any damage during transport.

- The wrapped equipment is then placed in a sturdy cardboard box with sufficient cushioning to absorb any impact during shipping.

- The box is sealed with high-quality tape to ensure it remains intact during transit.

Shipping Process

- We offer various shipping options to cater to our customers' specific needs and preferences.

- Our shipping partners are carefully selected to ensure timely and efficient delivery of our products.

- All shipments are tracked and monitored to provide real-time updates and ensure the safe arrival of our products.

Our team takes great care in packaging and shipping our Cementing Float Equipment to ensure it reaches our customers in perfect condition. For any additional packaging or shipping requests, please contact our customer service team.

FAQ:

-

Q: What is the brand name of this product?

A: The brand name of this product is sws.

-

Q: What is the model number of this product?

A: The model number of this product is 5.

-

Q: Where is this product made?

A: This product is made in China.

-

Q: What is the purpose of Cementing Float Equipment?

A: The purpose of Cementing Float Equipment is to provide buoyancy and prevent backflow during cementing operations in oil and gas wells.

-

Q: What sizes are available for this product?

A: This product is available in various sizes to fit different casing sizes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!